Testing is one of several tools for verifying compliance with the NCC, and it’s certainly the most hands-on (and the most fun). What follows is a peek behind the curtain at the process and how it produces results that can be relied on for the design life of the structures our connectors are used in. For nails, screws, nailplates, and brackets this process is outlined in the fasteners and connectors testing standard, AS1649.

Exploration and prototyping

The AS1649 authors understood that the formal testing protocols it requires would be the last step, not the first one. “The Standard presumes that before any of the described tests…are commenced some exploratory testing would be expected.”

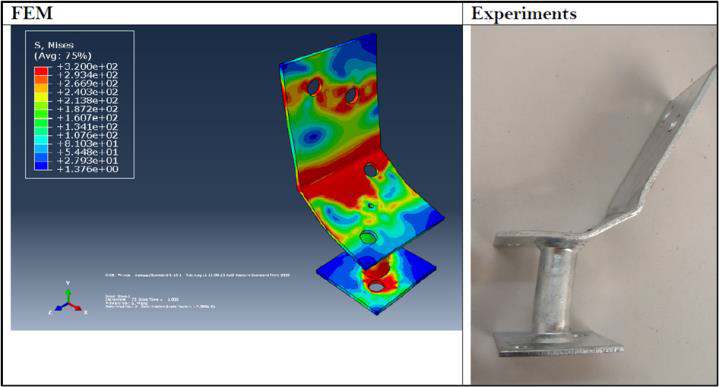

There are some powerful analytical tools available to engineers these days which can provide useful insights into how a component will perform before it’s even made.

These mean you can (virtually) poke, prod, and experiment with a product in as many scenarios as you can imagine and compare a range of design options before you even think about bending and cutting metal.

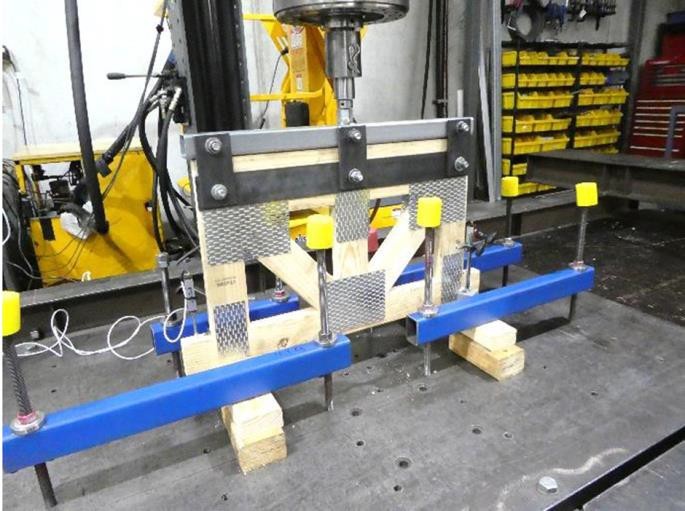

When it comes to the physical product, though, a range of other factors can impact its performance. Does it come out of the factory as per the drawing/model? Are the manufacturing tolerances the right balance between delivering a product that will perform consistently over time, and one that is practical to make? Can the assumptions I made in my computer model be replicated in the real world, repeatedly, by the end users when they install it?

This where getting into a lab (and often breaking things) comes into its own.

Formal independent testing

The NCC lists a report by a “registered testing authority” as one of several ways to demonstrate compliance with the code. In Australia, “registered” means accredited by the National Association of Testing Authorities (NATA), who assess and certify labs to perform specific tests. This is important to note – NATA’s scope is incredibly broad and being ‘NATA-certified’ is meaningless if that certification doesn’t cover the tests being performed. They may know everything about specialist medical equipment and nothing about structural engineering.

Achieving and maintaining NATA accreditation involves a thorough assessment of a lab’s management systems, staff, testing methods, quality control, equipment (including calibration), results recording and its operating environment. As much as we enjoy doing our own experimentation, the level of expertise, quality, and value that can be added by NATA-certified professionals is an important part of our overall testing and certification process.

Bringing testing into the 21st century

When AS1649 was written, the statistical methods needed to convert raw testing data into a capacity value with a known degree of confidence were too time consuming to be standard practice. These days they’re a simple function in Microsoft Excel. A new industry committee has recently formed to explore how we can modernise testing and data analysis methods so that we can be faster, more agile, and more confident in our results.

This project was initiated by Swinburne University and is being broadly supported with sponsorship, products, and technical input from the industry to help ensure timber connections are designed as reliably and efficiently as possible.

Ultimately this process is all about supporting the success of timber as the building material of choice for lightweight framing. Testing helps us get the products right, get them used correctly, and ensure they deliver what they promise.