Pryda Technical Manager

Once a quarter we are invited to contribute the Tech Talk column in the FTMA newsletter. For this month’s Tech Talk I’m zooming out from the details and looking at changes in the laws that govern who can provide technical advice and how it is communicated. Fundamentally this is great news for fabricators and will further highlight the value we add by solving problems and managing risk before the framing is even on site. ‘

From July 1 next year, Victoria and NSW will join Queensland in requiring engineers to be registered if they are to perform work for those states. Major stakeholders like Engineers Australia are pushing hard for this to be expanded to the remaining states, and with compulsory registration now inked into law up and down the East Coast it’s not hard to see the remaining dominos toppling in the next few years.

It’s easy to think of new regulations as an obstacle; more hoops to jump through, more forms to fill out, more fees to pay and so on. For fabricators, however, these new laws are an opportunity to double down on how we pitch the value of shifting work off site and into your yards. I’ll get to that, but first of all it’s important that you know what this means to you, as there are some longstanding ways of doing things that will come under scrutiny and could get you in hot water.

The critical thing to understand is when someone is deemed to be acting in the capacity of an engineer. The law allows non-engineers to work within the limits of “prescriptive standards”, and specifically calls out AS1684 as an example. As soon as you go outside these limits and need to use detailed calculations and/or engineering judgement to come up with a solution you’re operating as an engineer. This means you either need to be registered or closely supervised by someone who is and can approve the work.

As a practical example, I know may detailers have useful rectification details pinned to a corkboard or stuck to the wall ready to go the next time a similar situation comes up. The key question is: who is making the decision about whether that previous detail is suitable for a different job?

Significant fines and jail time are possible if a detailer makes a judgement call that the detail can be re-used and they are found to have been working as an engineer under the definitions in the legislation. This applies both to them and to their employer.

That’s the stick; now for the carrot I promised.

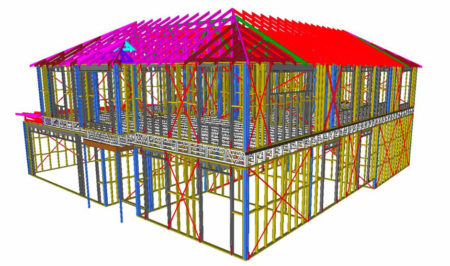

For starters, we have some very clever software in this industry that absorbs a significant amount of the engineering and compliance responsibility. The chain of paperwork and approvals from detailer training through to a job’s Producer Statement provides clear traceability back to the requirements of the NCC and the Australian Standards, giving certifiers confidence that their risk is managed when they give offsite-manufactured frames and trusses the tick of approval.

The nature of prefabrication also forces a lot of problems to be solved before any timber is even cut. This is the fundamental value of building off site. We apply our collective smarts to the front end of the project and greatly reduce the decisions that need to be made during construction. Once again there is full traceability for the certifier back to either the software output or the formal advice of a registered engineer.

If you’re not already in the habit of getting everything in a written format that clearly shows the credentials and registration status of the design engineer, now is the time to have that conversation with your nailplate company. It’s also an opportune time to think about investing some upfront effort in standardised engineering details that can be re-used within some clear parameters rather than working job to job. You may find it’s a smarter way of working for detailers and engineers, as well as a neat way of managing compliance with the new legislation.

We can also continue to shift decisions and labour from the site to the yard. Pre-installed connections and supplying ancillaries reduce the chances of products being installed incorrectly or a non-engineer making an illegal judgement call to swap out a product or change a detail.

With certifiers under increasing scrutiny and facing rising insurance premiums they are looking for certainty and – here’s that word again – traceability. Being able to quickly match what’s on site to what’s on the project documentation promotes confidence in the prefabricated components and underlines their value compared to the stick-built alternative.

Your nailplate company will be working in the background on making sure their engineering advice is in line with these new requirements, so let’s all make sure that builders also understand that changes are coming. It’s a perfect opportunity to double down on the safety, speed, quality and confidence of using prefabricated timber framing by showing builders that we are the ideal partner to navigate increasingly strict compliance requirements.