Adjustable up to 25 tonnes of pressing force

Interlocked two-hand control operation

Top platen swivels to the rear to clear the work surface

Hydraulic system ensures a fast cycle time and an efficient 1 HP motor

Many years of use in the timber industry

Ergonomic working height

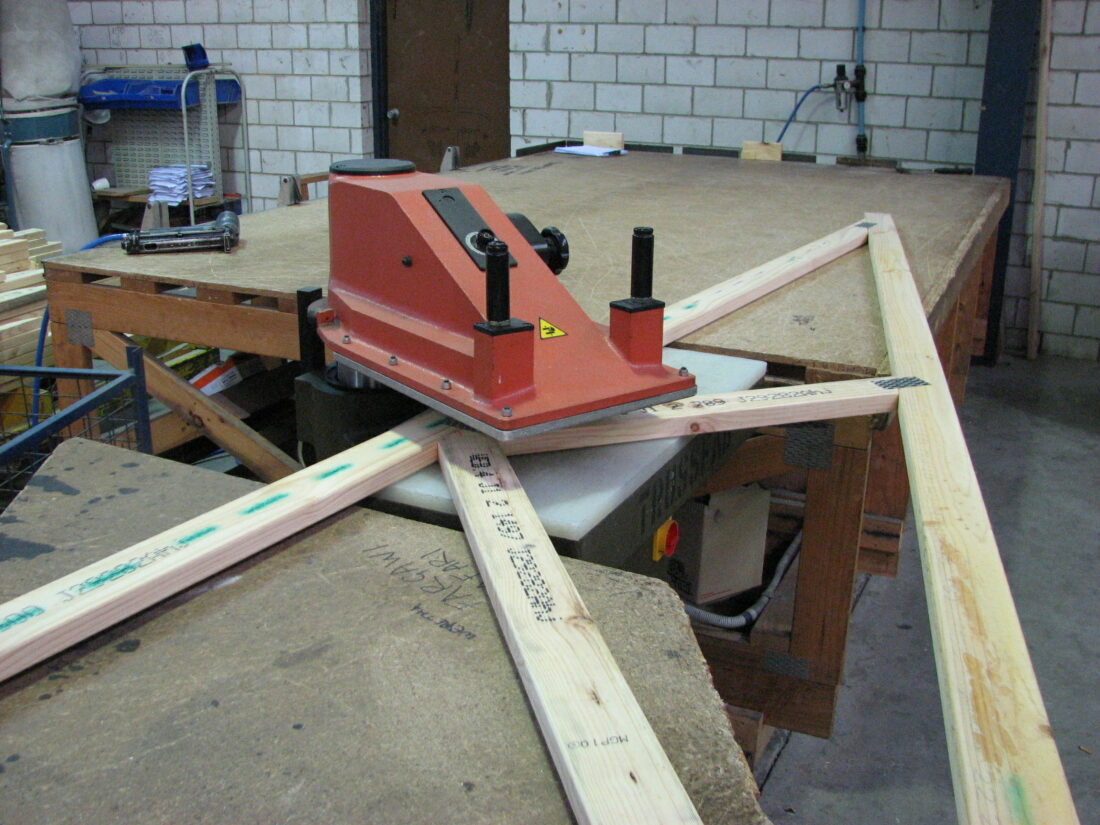

CLICKA PRESS

The Clicka Press has been used within the roof truss industry for some years in Australia and

overseas. It is a very simple but robust piece of equipment that achieves its desired purpose for

minimal capital cost.

The simple pushbutton operational controls include a two-hand interlocked safety system that

will immediately cease downward pressing once either button is released. Both buttons must be

pressed within 0.5 seconds of each other.

A swivel head design of the top platen allows operators to have a clear work surface prior to

pressing. Its effortless movement ensures minimal operator fatigue.

The unique and efficient hydraulic system allows a pressing force of up to 25 tonnes with a

relatively small electric motor. The pressing force and stroke can be easily adjusted on the press

head.

The system’s compact design allows for very easy installation that can be carried out by most

production staff.

SPECIFICATIONS

| Dimensions | ||

| Press capacity (tonnage) | 25T adjustable | |

| Overall dimensions (std unit) | ||

| – Width | 1000m | |

| – Depth (overall) | 1020mm | |

| – Height (overall) | 1410mm | |

| Motor size | 1.0HP | |

| Maximum stroke | 90mm | |

| Platen size (upper) | – Width | 500mm |

| – Depth | 450mm | |

| Weight (approx) | 1200kg | |

| Installation requirements | ||

| Power | 415V, 3 Phase, 10A | |

| Air | N/A | |

| Foundation | Level, sound concrete floor in both directions |

DOWNLOAD BROCHURE

RELATED PRODUCTS

- Roller conveyors

- Assembly benches

- SpeedTrussTM Jigging

- Magnetic Jigging

- Pryda Production Viewer