1 Sort; 2; Set in order; 3 Shine; 4 Standardise; 5 Sustain

Set up a solid foundation for future projects

Decrease your downtime

Increase your safety footprint along with productivity

Inspection simplification

5S implementation

5S describes how to organise your manufacturing and office space for efficiency by identifying and sorting the items used, maintaining your equipment and associated tools. The decision-making process usually comes from a dialogue about standardisation, which builds understanding among employees of how they should do the work in their relevant area.

5S is simple to understand but can be difficult to implement. It requires involvement from everyone in your business.

But that’s where the difficulty ends.

The benefits of 5S make it all worthwhile:

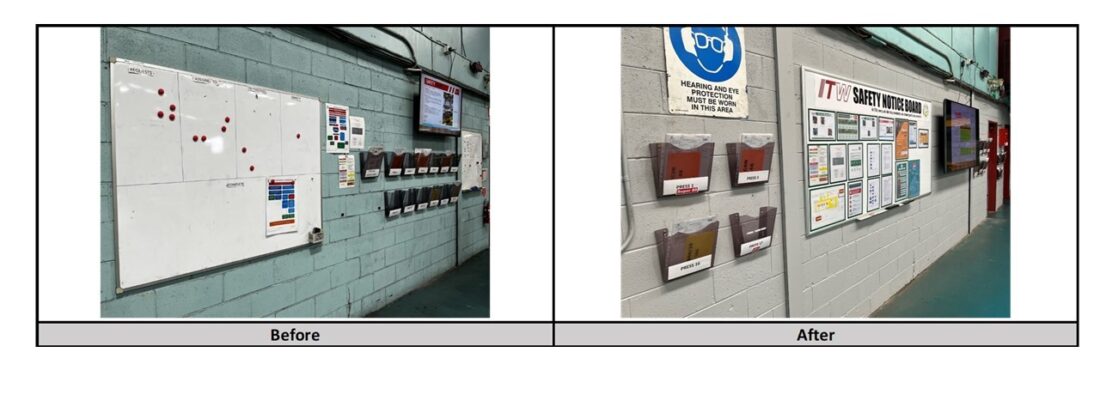

- Increased safety environment

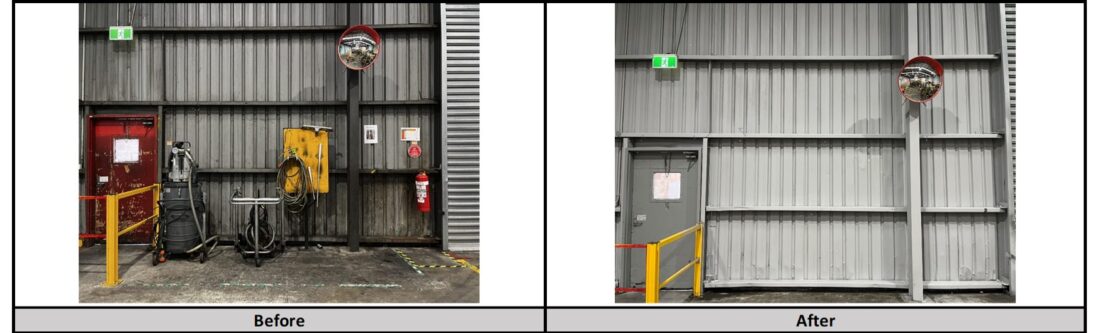

- Cleaner working areas

- Increased machine uptime

- Creates more space

- Identifies abnormalities

THE 5S PHASES AND THEIR ROLE IN WORKPLACE TRANSFORMATION

- Sort: The first step in the 5S process involves sorting through all workplace tools, materials, and equipment to identify what is necessary and what is not. Items that are not required are either discarded or relocated to a storage area. The goal is to remove clutter and keep only what is needed, ensuring a safer and more efficient workspace.

- Set in Order: In this phase, the necessary items are organised for optimal use. Operators determine the most logical and accessible locations for each tool, part, and material. Clear labelling and designated storage help reduce the time spent searching for items and eliminate confusion, enhancing safety and productivity.

- Shine: Shine emphasises cleanliness in the workspace. Operators take responsibility for keeping their areas clean and inspecting equipment regularly. This ensures that potential issues are identified early, reducing the risk of accidents and breakdowns.

- Standardise: Standardising the processes ensures that the first three phases — Sort, Set in Order, and Shine — are consistently maintained. Visual aids, checklists, and guidelines help operators understand expectations and maintain established standards.

- Sustain: The final phase is focused on sustaining the improvements made during the previous steps. This requires a commitment to continuous improvement and regular audits. Operator engagement is crucial in this phase to ensure that the gains from 5S are not lost over time.